On-Site Steel Reinforcement Installation: A Professional Approach for Your Build

On-Site Steel Reinforcement Installation: A Professional Approach for Your Build

Blog Article

Enhance Building Performance With Professional Steel Mending

In the realm of building and construction, the function of professional steel taking care of can not be overstated, as it straight influences both the structural honesty and performance of tasks. Knowledgeable steel fixers apply their proficiency to ensure exact positioning and safe and secure connecting of reinforcements, which is crucial in decreasing costly errors and maximizing product usage.

Value of Steel Repairing

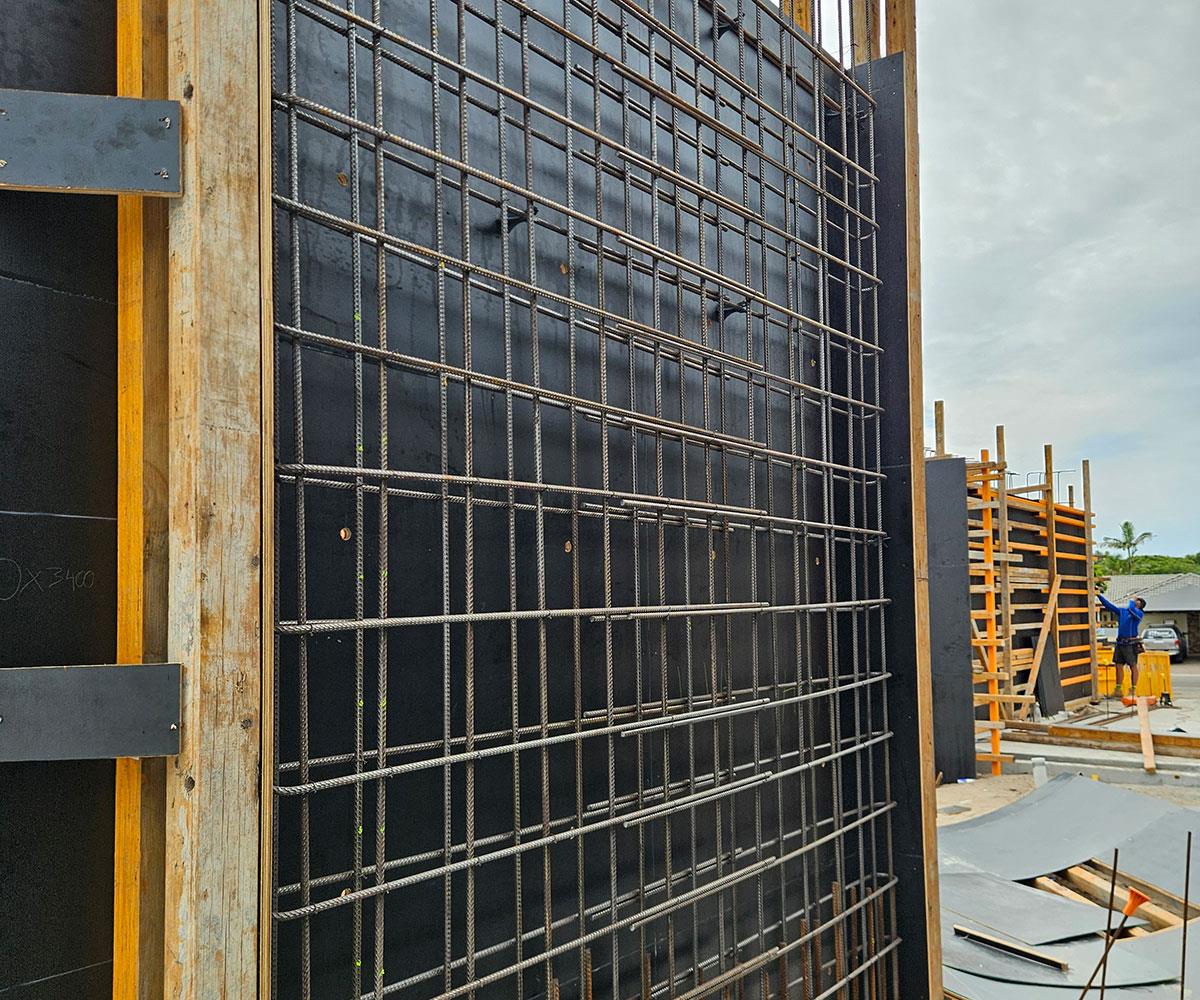

Why is steel fixing an essential part in building? Steel repairing includes the positioning and protecting of steel reinforcement bars (rebars) within concrete structures, making sure structural integrity and toughness. This process is vital in providing tensile strength to concrete, which inherently lacks this residential property. Without proper steel repairing, structures are at threat of failure under various lots, including compression, shear, and tension.

Additionally, the precision involved in steel fixing straight affects the overall high quality of construction. Accurate placement of rebars makes sure that designs are stuck to, minimizing the danger of architectural weak points. Steel dealing with adds to the efficient transfer of tons within a framework, enabling for the building of much safer and a lot more resistant buildings.

Along with improving architectural performance, steel repairing likewise contributes in maximizing building timelines. By making certain that steel reinforcement is appropriately placed prior to concrete is put, the threat of rework is significantly minimized. This structured approach not just saves time however additionally reduces overall job costs. Hence, recognizing the relevance of steel fixing is essential for specialists in the construction sector, as it develops the backbone of safe and lasting frameworks.

Benefits of Professional Expertise

Additionally, skilled steel fixers are proficient at analyzing building and design strategies. Their capability to properly translate styles right into functional applications reduces errors, therefore decreasing pricey rework and project hold-ups. Expert expertise also adds to enhanced security on website. Competent steel fixers are learnt industry criteria and finest techniques, which help to mitigate risks linked with steel work.

Furthermore, using expert services can result in more efficient usage of products. Professionals can maximize the amount of steel needed, thus reducing material prices and reducing waste. This effectiveness not just benefits the spending plan yet also aligns with lasting building methods.

Finally, relying on expert expertise cultivates a joint environment among designers, designers, and specialists, advertising smooth interaction and project implementation. In general, the advantages of professional experience in steel taking care of are very useful, dramatically impacting the success and quality of building and construction projects.

Techniques for Effective Steel Fixing

Reliable steel fixing methods are vital for making sure timely job conclusion and optimal architectural efficiency. One of the foremost methods entails accurate preparation and layout of rebar positionings based on structural illustrations. Utilizing innovative software for 3D modeling can facilitate far better visualization and sychronisation among the project group, reducing mistakes during installment.

In addition, using proper fastening strategies, such as cord linking or mechanical couplers, can enhance joint honesty and reduce labor time. Educating More about the author workers in best practices for safety and effectiveness is also vital, as proficient workers can carry out tasks faster and accurately.

Lastly, routine examinations during the installment procedure can help identify and correct potential concerns early, stopping expensive delays. By incorporating these methods, construction jobs can attain better efficiency and boosted structural high quality, ultimately supplying far better outcomes for stakeholders and clients.

Common Difficulties and Solutions

While applying efficient methods can considerably improve steel taking care of processes, various challenges usually develop that can restrain progression. One typical difficulty is the miscommunication in between groups, causing mistakes in steel placement and increased rework. To address this, establishing clear communication procedures and using sophisticated software program for control can boost precision and team effort.

An additional substantial issue is the variability in website conditions. Unanticipated elements such as climate changes or ground instability can interrupt steel fixing procedures. An aggressive remedy entails performing thorough site evaluations and having backup strategies in location to alleviate prospective delays.

In addition, labor shortages can impede the prompt completion of steel repairing jobs. Spending in training programs and promoting a culture of ability growth among workers can help connect this void.

Lastly, poor precaution can present threats to both employees and the task timeline. Implementing strict safety protocols and routine training sessions can enhance worker safety and minimize accident-related disruptions. By identifying these challenges and applying efficient services, construction professionals can guarantee an extra effective and trusted steel taking care of process, inevitably leading to successful project outcomes.

Influence On Project Timelines

The impact of steel taking care of on project timelines is a critical consideration for building and construction experts. Reliable steel fixing straight influences the total schedule, as hold-ups in this phase can lead to significant troubles in succeeding building activities. Effectively implemented steel repairing ensures that the structural integrity of the job is attained in a prompt fashion, promoting a smooth shift to the following phases of construction.

When steel taking care of is performed by proficient professionals, the risk of errors and rework is lessened, promoting adherence to the intended timeline. Alternatively, substandard steel dealing with can lead to costly hold-ups, requiring added time for inspections and improvements. The integration of innovative techniques and technologies in steel repairing, Visit Website such as 3D modeling and prefabrication, can additionally improve effectiveness, enabling quicker installment and minimized labor prices.

Additionally, timely conclusion of steel fixing effects the organizing of various other professions, such as concrete ending up and putting job. steel fixing. By prioritizing expert steel dealing with, building teams can efficiently manage their timelines, making sure jobs are supplied on time and within budget plan. Ultimately, purchasing top quality steel taking care of solutions is essential for maintaining task momentum and achieving effective end results

Conclusion

Finally, expert steel repairing plays a crucial duty in enhancing building and construction efficiency by ensuring the accurate placement and safe and secure tying of steel supports. The adoption of sophisticated techniques, such as 3D modeling, streamlines the installment process, reducing mistakes and rework. Cooperation amongst professionals, engineers, and designers better enhances job results, inevitably adding to the structural stability and resilience of concrete frameworks. Focusing on specialist experience in steel dealing with is essential for the success of construction projects.

Steel repairing involves the placement and safeguarding of steel support bars (rebars) within concrete structures, making sure architectural stability and durability. Experienced steel fixers are trained in industry requirements and best techniques, which assist to weblink alleviate threats associated with steel job.

By recognizing these challenges and implementing effective remedies, construction experts can guarantee a more reliable and dependable steel repairing procedure, inevitably leading to effective task outcomes. (steel fixing)

By prioritizing specialist steel taking care of, building teams can properly handle their timelines, making certain jobs are supplied on schedule and within spending plan.In verdict, specialist steel fixing plays a vital duty in boosting building effectiveness by ensuring the precise positioning and safe linking of steel supports.

Report this page